Specialties: Comminution Circuit Design, Comparing HPGR, SAG Mills, AG Mills, Crushers

- Drill to Mill Plant Optimisation Throughput forecasting

- Diamond, Gold, Iron ore, Copper, Vanadium, Lead, Zinc, Aluminum, Rare Earths Processing

- Conventional HPGR versus SAG trade off studies.

- HPRC versus AG mills

- Conventional Crushing

- Scrubbing Plant Design.

- Economies of scale studies.

- Ore Characterization and Data Analysis.

- Comminution tests: SPI, Axb, Bwi, Rwi,Cwi, Geometallurgy.

- Comminution test (SMC Test®, DWi, Mia, Mib, Mic, Mih).

- Modelling and Simulation (critical review of competitors)

- Specialties: Project peer review (Third party).

- Review of Sedar NI 43-101 technical reports : Process Section.

- Compiling of Sedar NI 43-101 technical reports : Process Section.

- Review engineering scoping/concept study, trade off study, PFS, FS.

- CB Vs. SAB Vs. SABC Vs. 2C/SAB Vs. 2C/HPGR/BM Vs. SS SAG Vs. ABC Vs. SS AG.

- Effect of Secondary Crushing

Service offerings from each of the business entities CMD and DMCC are interchangeable through mutual agreements and include the following technical topics:

- Equipment sizing

- Comminution circuit design

- Comminution technology selection

- HPGR versus SAG technology trade-off’s

- Existing comminution circuit optimisation

- Multiple method comminution data analysis

- Supervise test work programs and site surveys

- Geo-metallurgical and forecast production models

- Flowsheet design & optimisation- (modelling & simulation)

- Large scale diamond plant circuit design (economies of scale)

- Eco-comminution circuit design® www.cmdconsultulting.com.au

- Project management - (commercial and academic environments)

- Integrated blasting, crushing and milling studies with http://www.esenmining.com/

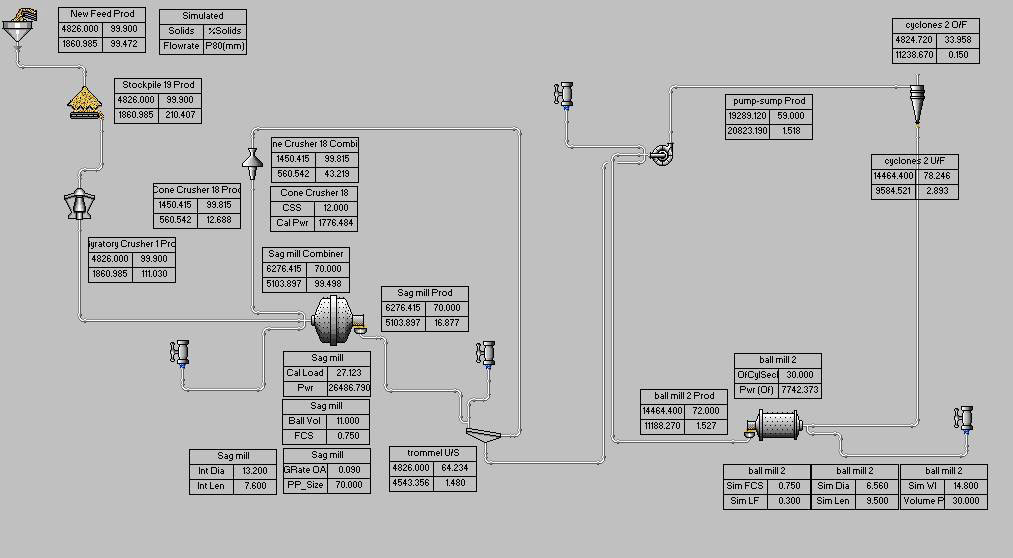

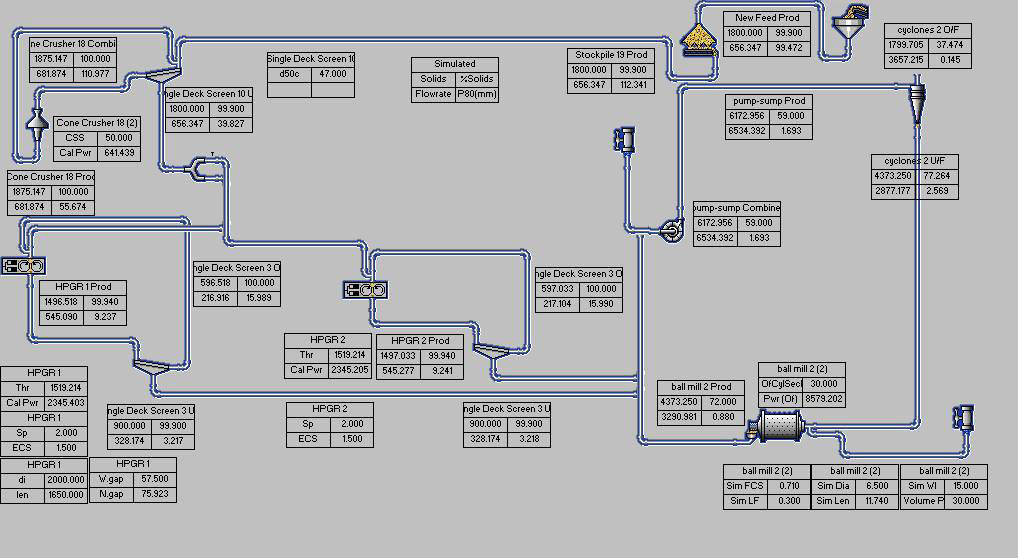

- JKSimMet Modelling and Morrell Power Modelling (20150821_Morrell_Method-GMSG-ICE-v01-r01-)

Training : Two day interactive comminution course

Session 1

- Discussing Comminution energy: How much is a lot?

- Energy consumption in the mining industry and its importance.

- Direct (electrical) versus indirect (embodied) energy usage.

- Circuit Specific Energy and Ore type.

Session 2

- Ore Characterization Tests

- Bond theory, CWi, RWi, BWi

- SMC Test®, Mia, Mib, DWi, Mih, Mic

- HPGR and SAG Pilot Testing.

Session 3

- Circuit Design Concepts

- Economies of Scale, Have we reached the limit?

- Ore type and grind size.

- SAG Vs.. HPGR Vs.. Crushing Vs. Ball Milling.

Session 4

- Worked example - Total circuit specific energy, which circuit is best for me?

- Worked Example – Evaluating the performance of an SABC circuit

Session 5

- Mill power draw modelling

- Effect of mill speed, mill filling, ball charge and slurry density.

- Fully autogenous (AG) versus Semi-Autogenous (SAG) milling.

- Morrell power model versus other published models

Session 6

- Circuit Modelling and Engineering Trade Off Studies

- Using Comminution Data in JKSimMet.

- Demonstrate Power Draw Analysis in Comminution Equipment.

- Evaluation of SAG versus HPGR versus Crushing in JKSimMet.

- Secondary crushing as an option, when your circuit is in trouble

Session 7

- Modelling

- Advances in Dem modelling

- Modelling particulates

- Modelling of breakage

- Modelling wear

- Modelling Crushers, Mills, Conveyors and Chutes

- A transition period from Plant Design to Plant

- Optimization • Shifting goalposts : Coarse Mineral Liberation and Mill Operating Conditions

- Modelling Mills using DEM modelling techniques to better understand emerging liner design.

Session 8

- Worked example - Predicting the power draw of a SAG/AG/Ball mill

- Worked example – Selecting the right circuit concept and equipment for duty

Sustainable process design for eco-comminution® circuits

Validated JKMRC HPGR modelling provides the ability to assess the power required in the grinding circuit. It then translates the power requirement into a range of options for HPGR selection and HPGR dimensions. After selecting a HPGR, the performance expected from the unit can be evaluated under a range of conditions such as changes to grinding force, rolls speed or rolls surface geometry. An appropriate motor size can then be recommended. If pilot plant data is available, JKSimMet is utilised to build a closed circuit model of the selected circuit. Pilot plant and predicted data from the model are then used as the basis for an engineering design brief. JKSimMet is particularly useful in assessing the transfer size from HPGR to ball mill or from SAG to ball mill.

Hence, complete circuits can be specified including SAG or autogenous mills, ball mills, screens and cyclones. Advice on the selection of mill liner type, profile and material can also be presented, tailored to the particular mills selected.